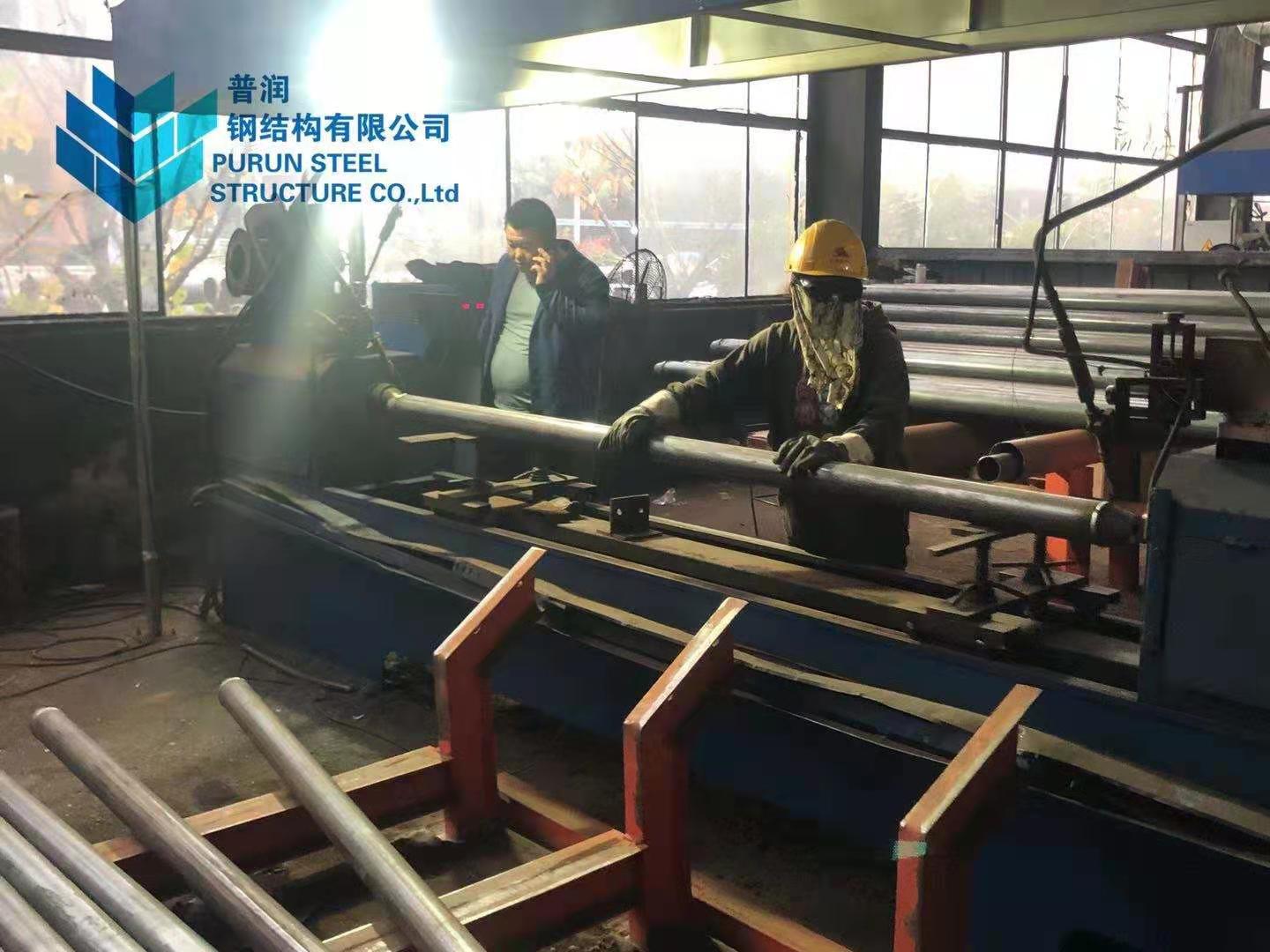

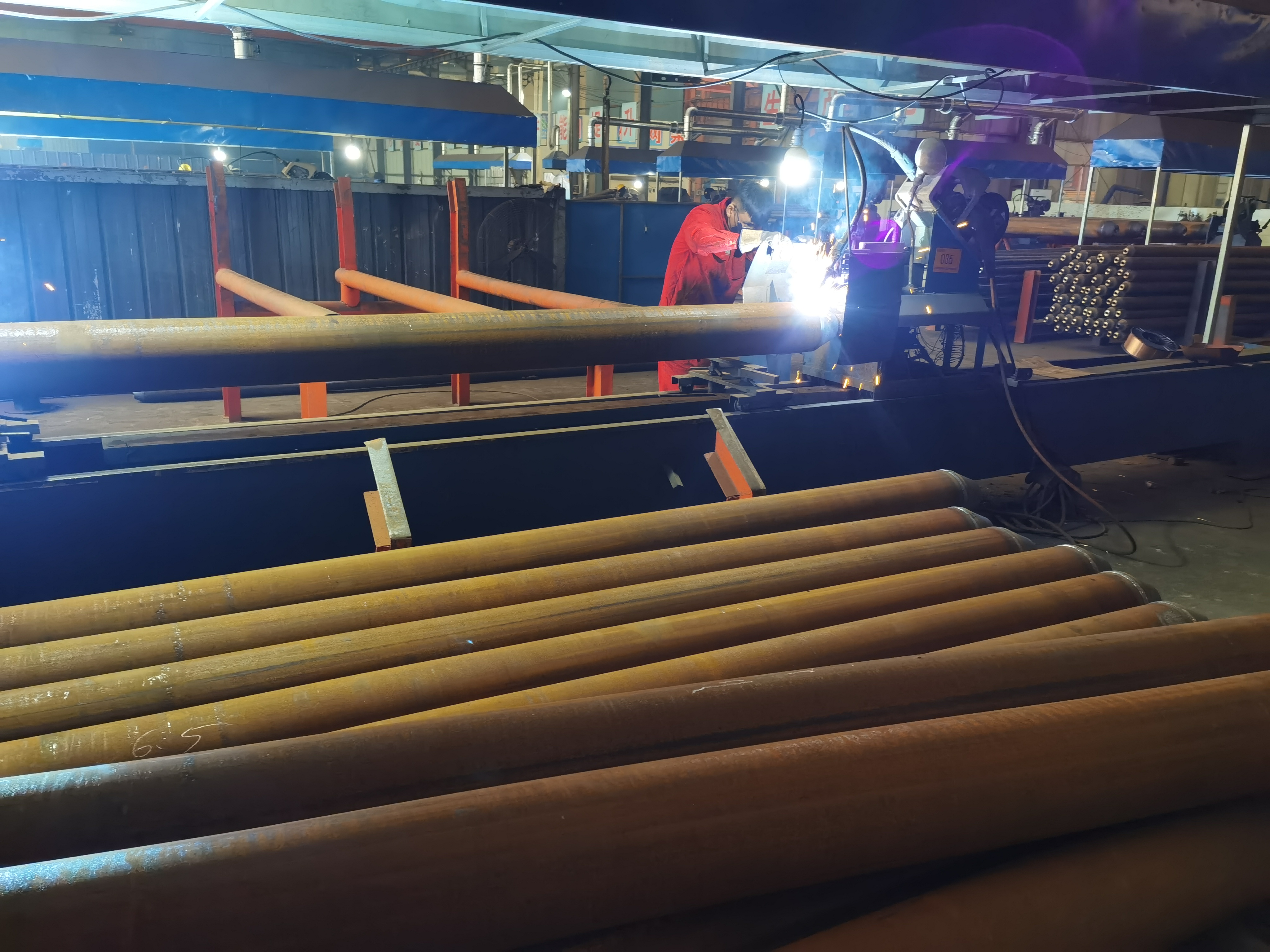

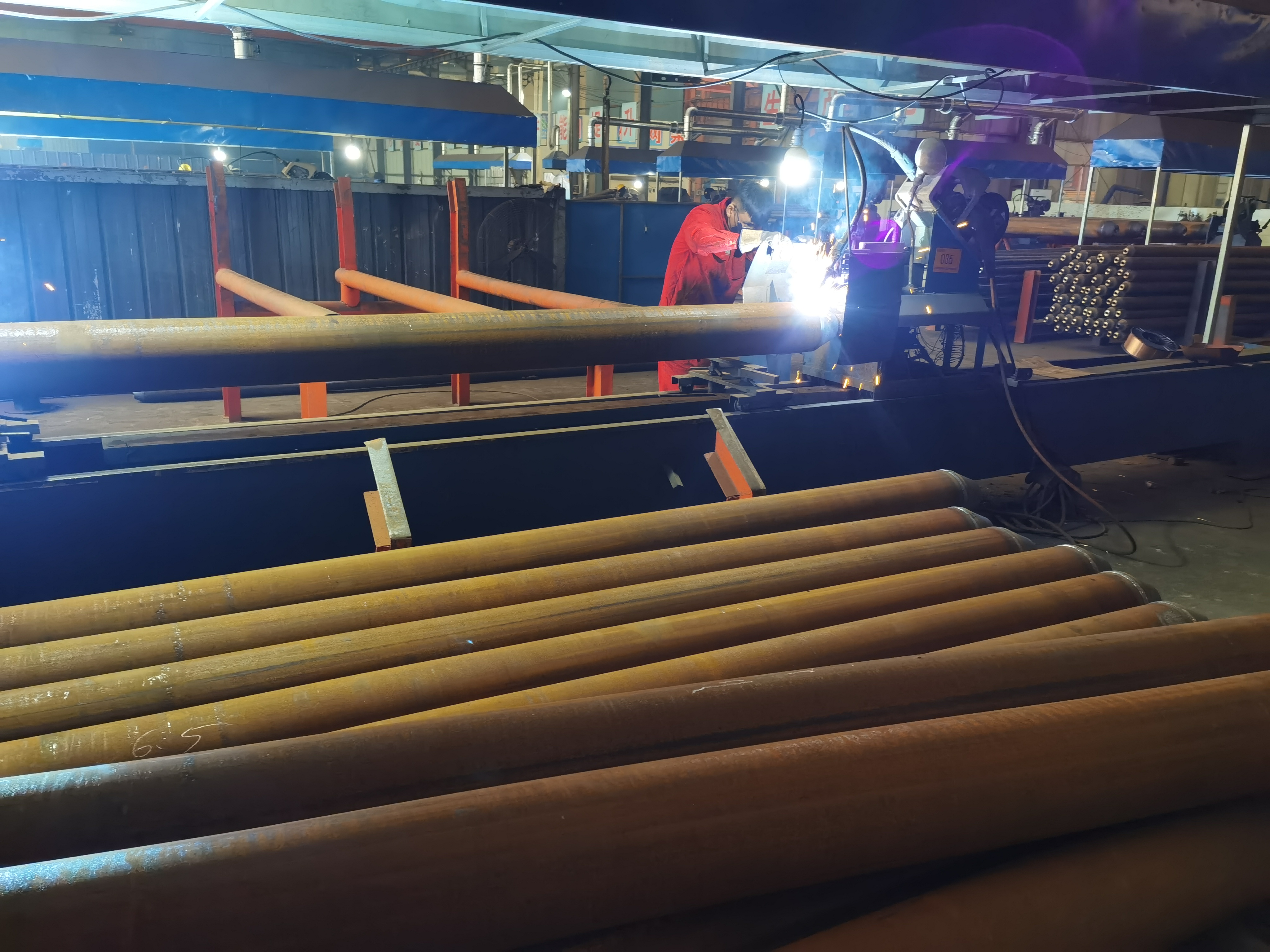

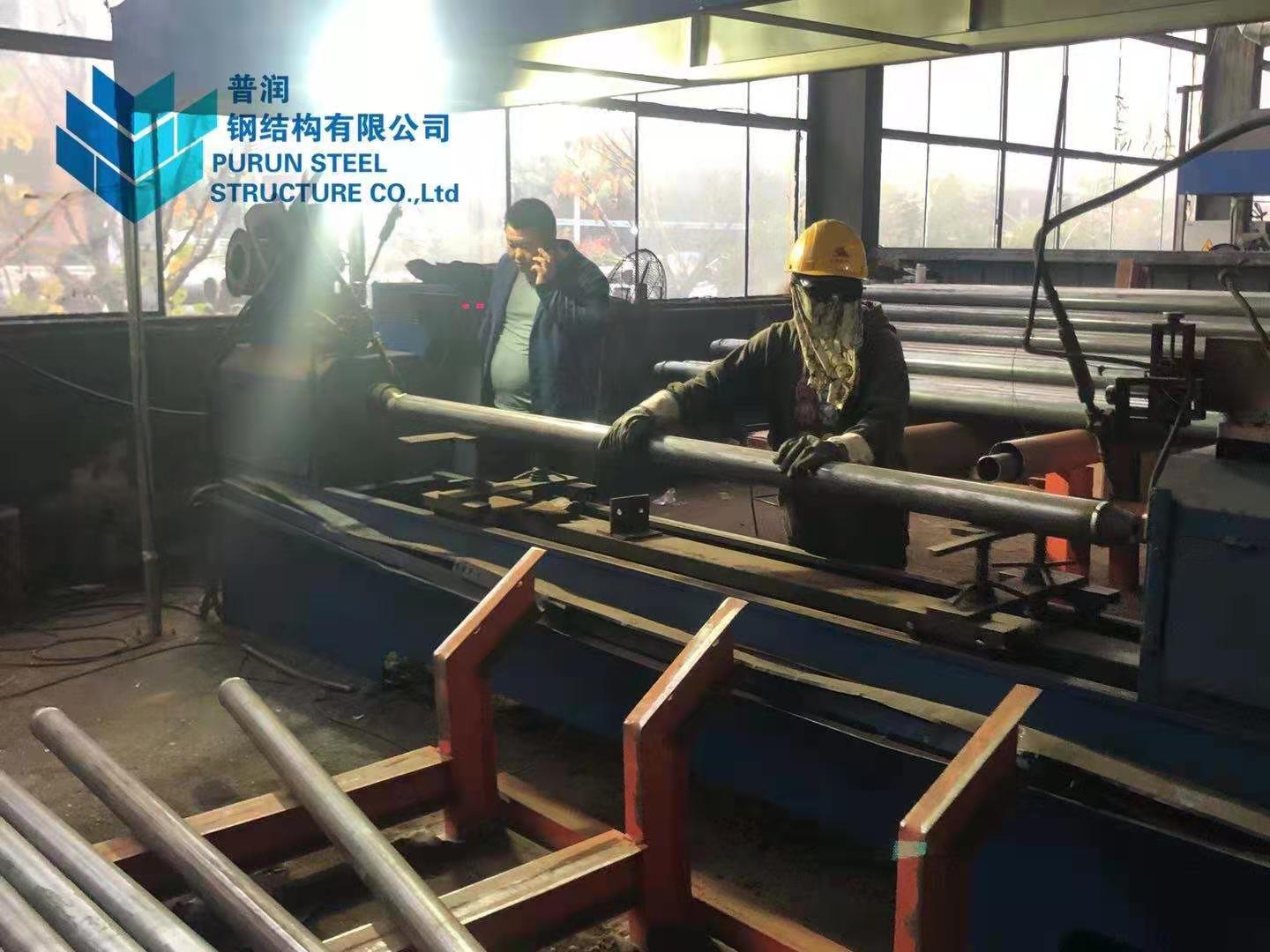

Ts'ebetso ea welding ea foreimi ea sebaka sa tšepe

welding:

Ts'ebetso ea tjheseletsa ke ts'ebetso ea bohlokoa tlhahisong ea foreimi ea sebaka sa tšepe, 'me e tlameha ho etsoa ho latela litaelo tsa ts'ebetso ea welding.Fokotsa khatello ea maikutlo e setseng e bakoang ke welding, 'me u lokise deformation ka nako ka ho futhumatsa lelakabe.

A. Ha phala ea tšepe e cheselitsoe ka poleiti e tiisang le phala ea tšepe, groove e tla buloa ho ea ka litlhoko, 'me angle ea groove e tla finyella litlhoko tsa angle e entsoeng pakeng tsa electrode le bokaholimo ba groove ho qoba kenyeletso ea slag.Ho phaella moo, lekhalo la groove le lokela ho ba Le leholo ka ho lekaneng e le hore arc ea electrode e ka fihla tlaase ho groove le ho qoba botebo bo sa lekaneng ba ho kenella.

B. Qoba ho beha seam ea welding bohareng ba molamu ha phala ea tšepe e koetsoe.

C. Litaba tse hlokang ho hlokomeloa ts'ebetsong ea ho cheseletsa:

a.Nakong ea li-arc welding, sebaka se tsamaisang ha sea lokela ho ba seholo haholo, 'me ho sebelisoa welding ea multipass le multilayer.

Nakong ea ts'ebetso, bead ea weld kapa interlayer welding slag, slag kenyelletso, oxide, joalo-joalo e lokela ho tlosoa ka thata.Lebili la ho sila, tšepe e ka sebelisoa.

Lisebelisoa tse kang borashe ba terata.

b.Sefate se tšoanang sa welding se lokela ho ts'oaroa ka mokhoa o tsoelang pele le ho phethoa ka nako e le 'ngoe.

c.Bakeng sa manonyeletso a fapaneng a weld, ka mor'a hore ho cheseha ho phethoe, slag le tšepe e fafalitsoeng holim'a weld e lokela ho hloekisoa.

Lekola ponahalo ea boleng ba weld, 'me ha hoa lokela ho ba le khatello ea maikutlo, weld bead, undercut, blowhole, khaello ea fusion, crack

le mefokolo e meng e teng.

d.Ka mor'a hore butt weld e chesetsoe, ho lemoha mefokolo ea ultrasonic ho lokela ho etsoa ka mor'a lihora tse 24.