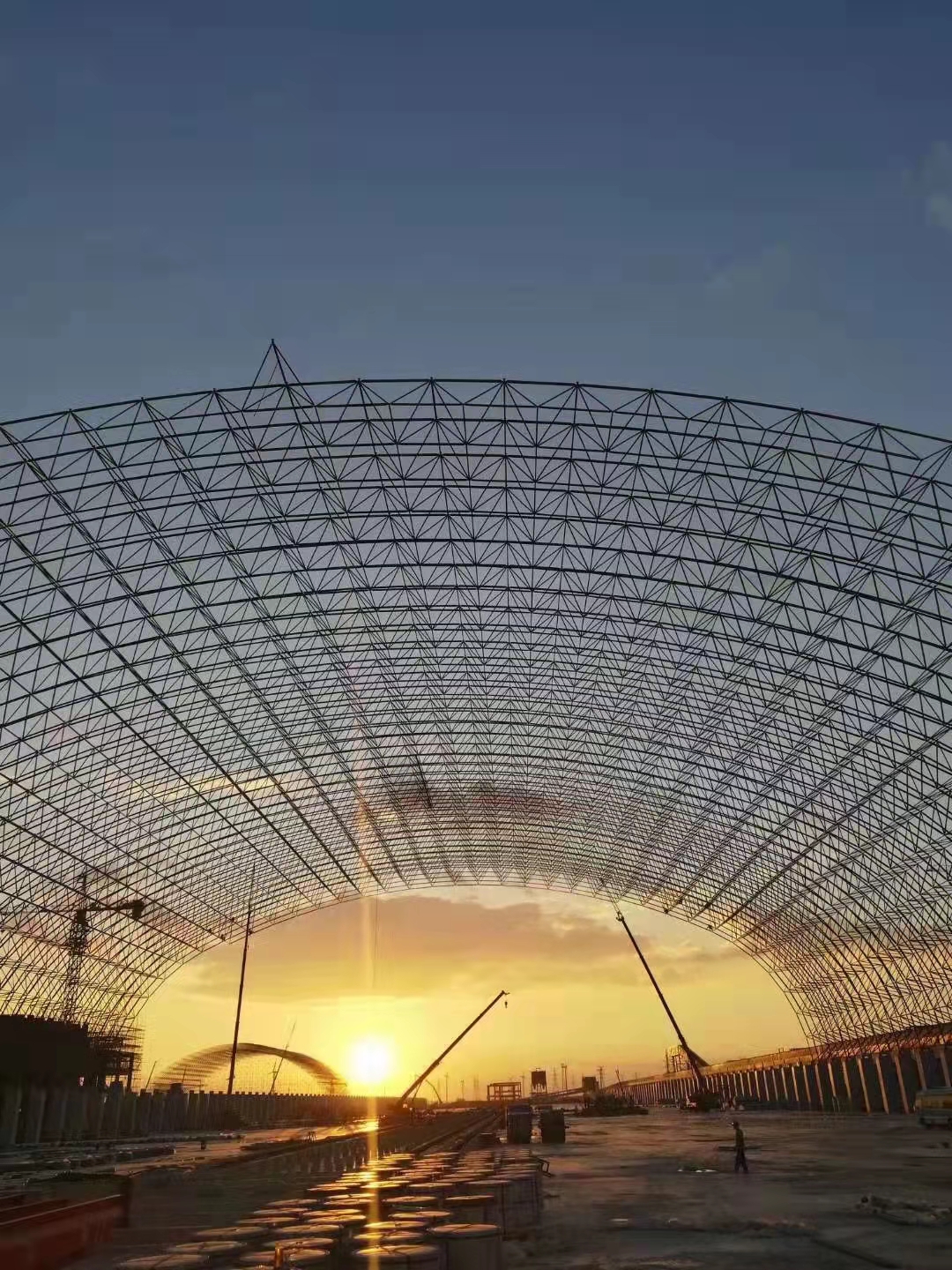

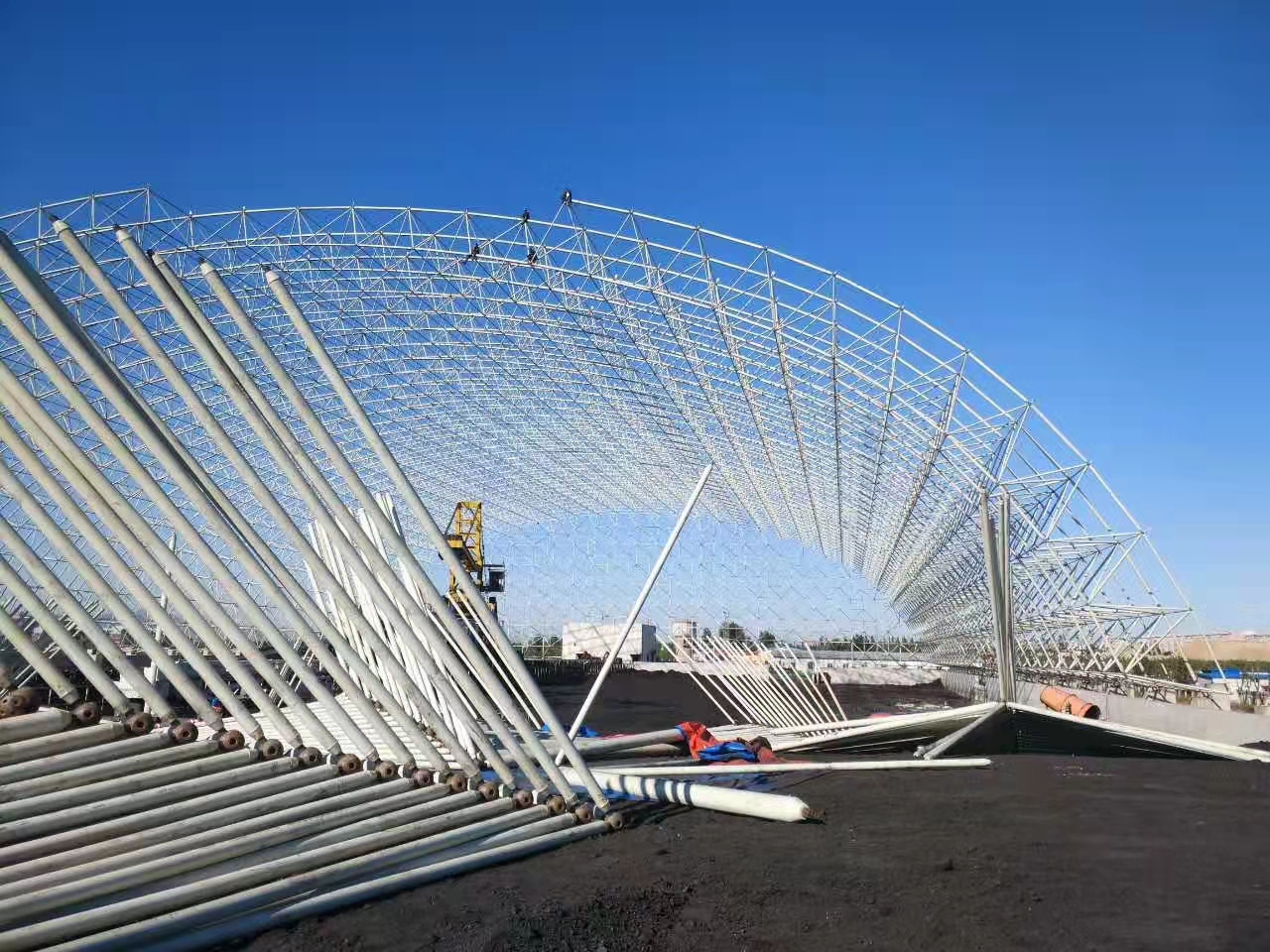

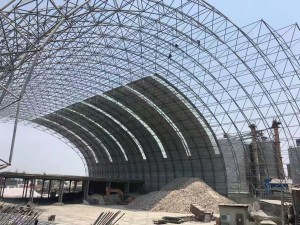

Ordos thermal power plant foreime ea sebaka sa tšepe se chitja

Raw material Q235B welded pipe / Bolelele bohle ke limithara tse 49 / Kakaretso ea bolelele ke limithara tse 96 / Bolelele bohle ke limithara tse 567.

1. Khetho ea thepa e lokela ho thehoa holim'a litifikeiti tsa boleng ba discretionary le litlaleho tsa ho hlahloba hape, ho latela maemo a hona joale a naha.

2. Pipe ea tšepe e amohela Q355B tšepe, phala ea tšepe e se nang moeli kapa phala e phahameng ea maqhubu a marang-rang (GB / T 700).

3. Li-bolts tse matla haholo li entsoe ka 40Cr tse tingoeng 'me li halefile le ho phekoloa mocheso ho ea ka "Technical Conditions for High-Quality Carbon Structural Steel Structures" GB/T 16939. Tshebetso ea bophara

4. Libolo tsa tšepe li entsoe ka lisebelisoa tsa tšepe tsa No. 45 tse lumellanang le "Technical Conditions for High-Quality Carbon Structural Steel" GB 699, e nang le matla a ho hlahisa 360N / mm2.

5. Letlapa le tiisang la hlooho ea cone le entsoe ka tšepe ea Q355B, 'me hlooho ea cone e entsoe ka forgings.

6. Nate e se nang khoele e entsoe ka likhoele tsa tšepe tsa Q355B.Ha bophara ba liboutu tse matla haholo ke> M30, sebelisa litšepe tsa tšepe tse 45-gauge.

7. Li-screws tsa fastening li entsoe ka 40Cr tse tingoeng le ho halefa.

8. Tšehetso e entsoe ka tšepe ea Q355B, 'me tšehetso e entsoe ka tšepe ea Q235B

9. Electrode e amohela letoto la E43XX;Letoto la E50XX (bakeng sa welding ea bolo ea bolt le likhopo tse jereng)

10. Li-purlins li entsoe ka tšepe ea Q235B e bōpehileng joaloka C.

11. Li-bolts tse tloaelehileng li entsoe ka li-bolts tse thata tsa sehlopha sa C tse entsoeng ka tšepe ea Q235B e finyellang litlhoko tsa boemo ba hona joale ba naha, 'me boemo ba ts'ebetso ke 4.8.

12. Li-electrode tsa welding le lithapo tse sebelisetsoang ho tjheseletsa li lokela ho finyella litlhoko tse nepahetseng tsa litekanyetso tsa hona joale tsa naha.The tjheseletsa pakeng tsa Q235B litšepe inkela E43 letoto la li-electrode, 'me tjheseletsa pakeng tsa litšepe Q345B amohela E50 letoto la li-electrode.

13. Lisebelisoa tsa marulelo: Sheba setšoantšo sa sebopeho sa marulelo a marang-rang bakeng sa lintlha tse ling.

14. Ntle le ho finyella litlhoko tsa boitsebiso ba naha, tšepe e sebelisoang morerong ona le eona e lokela ho finyella litlhoko tse latelang:

a) Karolelano ea tekanyo e lekantsoeng ea matla a tlhahiso ea tšepe ho ea ho tekanyo e lekantsoeng ea matla a matla ha ea lokela ho ba kholo ho feta 0,85;

b) Tšepe e lokela ho ba le mehato e hlakileng ea tlhahiso, 'me elongation e lokela ho ba kholo ho feta 20%;

c) tšepe e lokela ho ba le weldability e ntle le ho ba le tšusumetso e matla e tšoanelehang;